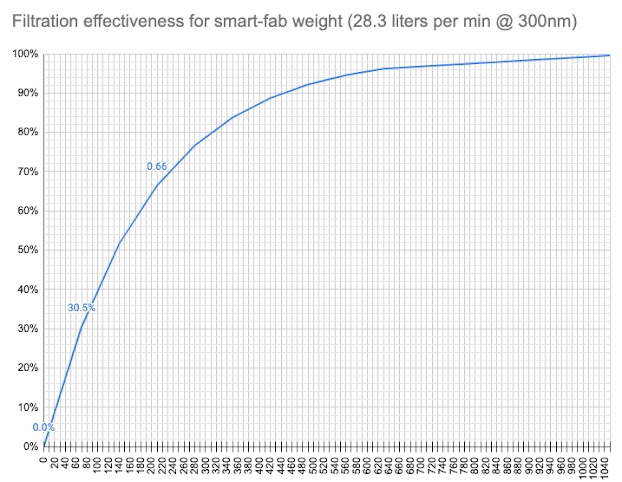

Filtration Effectiveness by Smart-fab weight

There's two weights of smart-fab, but that doesn't matter - they filter the same when you're adding up gsm. I'm going to call Spunbond Non-Woven Polypropylene SBPP henceforth

Here's the 38 gsm smart-fab called out by changing the spacing of the x-axis:

The graph isn't going to help if your adding any other fabric to the mix - it is only for masks made of smart-fab exclusively (or equiv SBPP), and there's assumption that you could make a mask that leaked at the edges similarly to the one that MakerMask shipped to Nelson labs. As it happens they sent three and there was variance. 66% is middle of the pack of the three - their datapoint. The 31% is calculated from their data using the layering formula.

Note that I have made a 1100gsm mask of the same SBPP.

You could put on a cotton outer. That itself is going to be between 10 and 30% protection. The higher the TPI the better the filtration, but that comes at a terrible price in terms of breathability (see below). If you need a pattern on the outside, perhaps choose these lowest TPI cotton your can get and don't count it at all towards filtration. You'd think higher TPI would be better but it is not - it decreases breathability and forces the air in (and out) at the sides of the mask, which is unfiltered. This is why medical folks obsess about "fit".

Note with the tests Aaron Collins did - getting about 85% with SBPP on its own. At a certain target for filtration you'll need a rubber seal at the edges (that fit issue). The fabric is fine for 94% as a target, but it is the edges that let the design down You also can't chuck a SBPP mask that has rubber edges in the washing machine, so it'd need to be removable somehow.

Note that https://www.3m.com/3M/en_US/p/d/v000436123/ is the logical conclusion of that last - the disks appear to be SBPP, but I bet they don't say whether they are washable or not.

Comments

Post a Comment